Supply Chain Disruptions and their Lingering Effects

While some areas have seen an easing of supply chain disruptions, significant challenges persist, particularly within specific sectors. The ongoing impact of these disruptions continues to ripple through global economies, influencing everything from the availability of consumer goods to the production costs of manufacturing. Understanding the nature and extent of these disruptions is crucial for navigating the current economic climate and planning for future resilience.

Port Congestion: A Persistent Bottleneck

Port congestion remains a major obstacle to the smooth flow of goods. A confluence of factors, including increased demand, labor shortages, and logistical inefficiencies, has led to significant delays at major ports worldwide. Ships are often forced to wait for extended periods to unload their cargo, leading to increased shipping costs and extended delivery times. This congestion is not limited to a few specific locations; it’s a global phenomenon affecting various regions and trade routes. The ripple effect is considerable, impacting businesses that rely on timely delivery of raw materials and finished goods. The lack of sufficient infrastructure and technological advancements in many ports further exacerbates the problem. Increased investment in port infrastructure and automation is crucial to alleviating these persistent bottlenecks.

Labor Shortages: A Critical Factor

Labor shortages across the supply chain, from dockworkers and truck drivers to warehouse personnel and factory workers, are significantly contributing to the ongoing disruptions. Several factors are driving these shortages, including demographic changes, an aging workforce, and difficulties attracting and retaining employees in demanding and often physically taxing roles. The pandemic further exacerbated these pre-existing challenges, leading to increased absenteeism and difficulty in filling vacancies. Competitive wages and improved working conditions are essential to attract and retain skilled workers, crucial to maintaining the smooth operation of supply chains. Technological solutions, such as automation and robotics, can also help mitigate the impact of labor shortages in the long term.

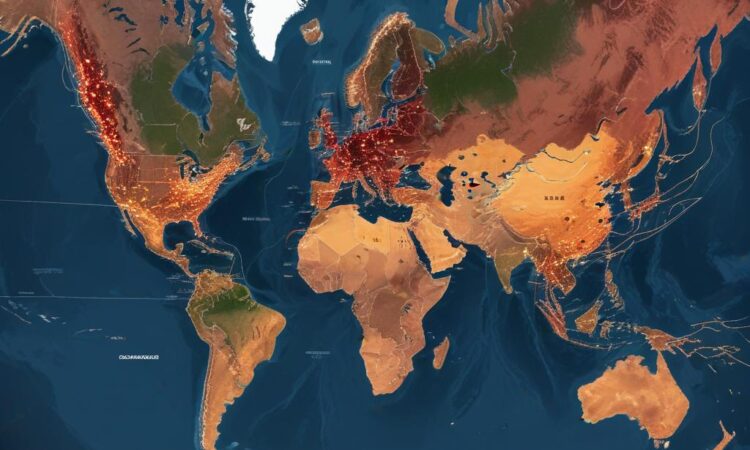

Geopolitical Instability: Adding to the Complexity

Geopolitical instability, including conflicts, trade wars, and sanctions, introduces an added layer of complexity to supply chain management. These events can disrupt trade routes, lead to increased uncertainty, and raise the cost of goods and services. Companies are forced to reassess their risk profiles and diversify their supply sources to mitigate the impact of these unforeseen circumstances. Geopolitical risk assessment has become a crucial element of strategic planning for businesses operating in the global market. Diversification, resilience planning, and risk mitigation strategies are paramount in navigating this volatile landscape.

Inflationary Pressures: A Direct Consequence

Supply chain disruptions are a major contributing factor to inflationary pressures worldwide. The increased cost of shipping, raw materials, and labor are directly passed onto consumers in the form of higher prices. This inflation affects various sectors, from food and energy to manufactured goods and electronics. Central banks are grappling with the challenge of controlling inflation while also supporting economic growth. Addressing the underlying supply chain issues is critical to mitigating these inflationary pressures and achieving long-term price stability.

The Resilience of Supply Chains: A Key Focus

Building more resilient and adaptable supply chains has become a top priority for businesses and governments alike. This requires a multifaceted approach, including diversification of sourcing, investment in technology and infrastructure, and improved collaboration across the supply chain. Developing more robust risk management strategies and enhancing transparency across the supply chain are also crucial elements of building resilience. Collaboration and information sharing between businesses, governments, and other stakeholders are vital to identifying and addressing vulnerabilities.

The pursuit of supply chain resilience necessitates a holistic approach. It involves not only addressing immediate challenges like port congestion and labor shortages but also proactively mitigating future risks. This includes proactively investing in digitalization, enhancing transparency, and establishing more collaborative relationships across the entire supply chain ecosystem. Furthermore, sustainable practices must be integrated to ensure long-term viability and environmental responsibility.

The ongoing disruptions underscore the interconnectedness of global economies and the vulnerability of supply chains to various shocks. By understanding the root causes of these disruptions and implementing comprehensive solutions, we can pave the way for greater resilience and stability in the long term. A collaborative, multi-stakeholder approach is paramount to achieve a more resilient and robust global supply chain system.

The long-term implications of these disruptions are significant and require a sustained focus on improvement. Continuous monitoring, strategic adaptation, and proactive investment are essential to ensuring the long-term health and stability of global trade and commerce. The development of more robust forecasting models and improved data analytics can also play a vital role in anticipating and responding to potential disruptions in the future. A commitment to innovation, collaboration, and sustainable practices is vital to building a more resilient and equitable supply chain system.

The challenges posed by supply chain disruptions are not simply temporary obstacles; they represent systemic vulnerabilities that demand comprehensive and sustained attention. Addressing these issues requires a concerted effort from governments, businesses, and international organizations, focusing on strategic investment, policy reform, and collaborative solutions.

In conclusion, while there are signs of improvement in certain areas, supply chain disruptions continue to present substantial challenges. Addressing these disruptions requires a comprehensive and proactive approach that considers all aspects of the supply chain, from sourcing and manufacturing to transportation and distribution. By focusing on building resilience, promoting collaboration, and fostering innovation, we can work towards a more stable and efficient global supply chain system that benefits all stakeholders.

The ongoing impact of these disruptions necessitates a long-term perspective, emphasizing proactive planning, robust risk management, and continuous improvement across the entire supply chain. Only through a sustained commitment to these principles can we navigate the complexities of the global marketplace and build a more secure and sustainable future.

The complexity of the current situation demands a multi-faceted response, encompassing investments in infrastructure, technology, and human capital, along with policy reforms that support the growth and development of resilient supply chains. This will ensure a greater degree of security and stability in the global economy for the years to come.

Furthermore, embracing sustainable and ethical practices throughout the supply chain is not only environmentally responsible but also contributes to building greater trust and transparency, enhancing the overall resilience and stability of the system. The future of global trade relies on a collaborative and forward-thinking approach to addressing the enduring challenges posed by supply chain disruptions.

Finally, the need for continuous monitoring, data-driven decision-making, and rapid adaptation to unforeseen circumstances cannot be overstated. The global landscape is constantly evolving, and only through a commitment to flexibility and continuous improvement can we truly achieve a resilient and sustainable supply chain for the future.