Supply Chain Disruptions and Their Economic Fallout

While easing in some areas, supply chain bottlenecks persist, impacting various sectors. Reports highlight ongoing challenges in logistics, manufacturing, and transportation, leading to higher costs and production delays. The impact varies across industries and regions, with some economies more vulnerable than others. Efforts to diversify supply chains and improve resilience are gaining traction.

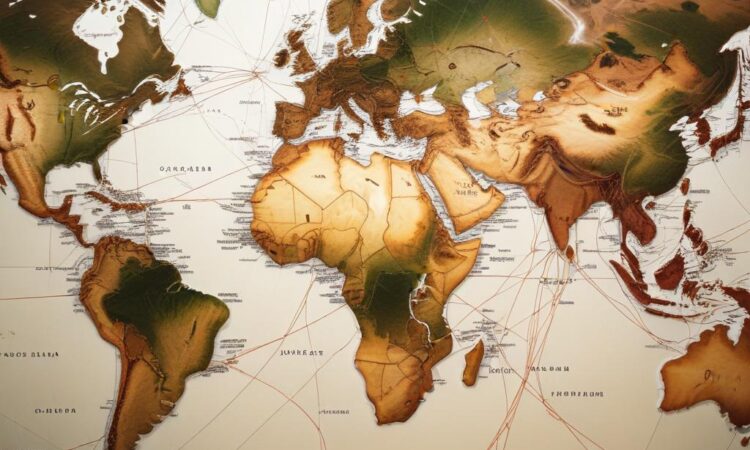

The global economy has been grappling with significant supply chain disruptions for the past few years, a phenomenon exacerbated by the COVID-19 pandemic and other geopolitical factors. These disruptions have manifested in a multitude of ways, causing ripple effects across numerous industries and impacting consumers worldwide. Understanding the nature and extent of these disruptions is crucial for navigating the current economic landscape and mitigating future vulnerabilities.

Logistics: The Backbone of Bottlenecks

The logistics sector, the lifeblood of global trade, has been particularly hard hit. Port congestion, a persistent problem in many major seaports around the globe, has led to significant delays in the movement of goods. Shipping container shortages and soaring freight costs have further compounded the issue, making it increasingly expensive to transport products from origin to destination. The lack of sufficient truck drivers and warehouse workers has also contributed to delays and inefficiencies within the logistics network.

The reliance on just-in-time inventory management systems, while efficient under normal circumstances, has proven vulnerable to disruptions. When unforeseen events occur, such as port closures or factory shutdowns, businesses find themselves lacking the necessary buffer stock to meet demand, leading to production halts and shortages.

Manufacturing: Facing Production Delays and Rising Costs

Manufacturers have faced significant challenges in securing raw materials and components due to supply chain disruptions. This has resulted in production delays, impacting the timely delivery of finished goods to customers. The increased cost of raw materials, transportation, and labor has also squeezed profit margins, forcing manufacturers to raise prices or absorb losses.

The automotive industry, for example, has been severely impacted by semiconductor chip shortages, leading to production cuts and long waiting lists for new vehicles. This shortage highlights the interconnectedness of global supply chains and the potential for a single bottleneck to have cascading effects across multiple sectors.

Transportation: A Multimodal Challenge

Supply chain disruptions are not limited to a single mode of transportation. Challenges exist across the board, encompassing sea freight, air freight, and road transport. The lack of available shipping containers, increased fuel prices, and port congestion have all contributed to significant delays and increased costs for businesses relying on these modes of transportation.

The increasing reliance on global trade has made supply chains more complex and vulnerable to disruptions. The geographic diversification of manufacturing and sourcing, while offering some benefits, also adds to the complexity of managing these intricate networks.

Economic Fallout: A Wide-Ranging Impact

The economic fallout from supply chain disruptions has been widespread and significant. Higher prices for goods and services have contributed to inflation, impacting consumer purchasing power. Businesses have faced increased costs, reduced profits, and difficulty meeting customer demand. The uncertainty surrounding supply chain disruptions has also dampened investment and economic growth.

The impact of supply chain disruptions varies across industries and regions. Some economies, particularly those heavily reliant on specific sectors or regions for their supplies, are more vulnerable than others. Developing countries, often lacking the resources and infrastructure to cope with disruptions, are particularly susceptible to the negative consequences.

Building Resilience: Diversification and Innovation

Efforts to diversify supply chains and improve resilience are gaining momentum. Businesses are exploring alternative sourcing options, investing in inventory buffers, and adopting more robust risk management strategies. Technological innovations, such as blockchain and AI, are also being leveraged to improve supply chain visibility and efficiency.

Government policies play a crucial role in building more resilient supply chains. Investing in infrastructure, promoting diversification, and fostering international cooperation are all essential steps in mitigating the risks associated with future disruptions.

The ongoing supply chain challenges underscore the need for a more holistic and proactive approach to managing global supply networks. A focus on diversification, resilience, and technological innovation is critical for ensuring the smooth flow of goods and services, and for mitigating the economic fallout of future disruptions.

Further research and analysis are necessary to fully understand the complex interplay of factors contributing to supply chain disruptions and to develop effective strategies for addressing these challenges. The development of more robust forecasting models, improved risk assessment methodologies, and collaborative partnerships between businesses, governments, and international organizations are essential for building a more resilient and sustainable global economy.

The ongoing evolution of global trade patterns and technological advancements will continue to shape the landscape of supply chain management. Adaptability, innovation, and a long-term perspective are crucial for navigating the complexities and uncertainties inherent in this dynamic environment. The focus must shift from simply reacting to disruptions to proactively building more robust and resilient systems capable of withstanding future shocks.

The interconnectedness of global supply chains means that disruptions in one area can have cascading effects across multiple sectors and regions. This highlights the need for a coordinated and collaborative approach to addressing these challenges, involving businesses, governments, and international organizations working together to build a more resilient and sustainable global supply chain system.

Furthermore, the increasing importance of sustainability and ethical sourcing adds another layer of complexity to supply chain management. Businesses are increasingly under pressure to ensure that their supply chains are environmentally responsible and socially equitable, adding further considerations to the already intricate process of managing global networks.

In conclusion, supply chain disruptions represent a significant challenge to the global economy, with far-reaching implications for businesses, consumers, and governments alike. While some easing of bottlenecks has been observed in certain areas, ongoing challenges persist, highlighting the need for sustained efforts to improve resilience, diversify supply chains, and adopt innovative solutions to ensure the smooth and efficient flow of goods and services in the years to come.

The need for collaboration and coordination across various stakeholders, including governments, businesses, and international organizations, is paramount in effectively addressing these ongoing challenges and building a more robust and resilient global supply chain system.

The future of supply chain management will likely be characterized by greater transparency, traceability, and sustainability. Embracing technological advancements, fostering collaboration, and prioritizing resilience will be crucial for navigating the complexities of the global supply chain landscape and ensuring a more stable and prosperous global economy.

The ongoing efforts to improve supply chain resilience underscore the importance of proactive risk management, strategic planning, and a commitment to continuous improvement. By learning from past experiences and adapting to evolving challenges, businesses and governments can work together to build a more resilient and sustainable global economy.

The long-term implications of supply chain disruptions highlight the need for a fundamental shift in thinking, moving from a reactive to a proactive approach to managing these intricate networks. This requires a holistic strategy that addresses various aspects of supply chain management, from sourcing and manufacturing to logistics and distribution.

Finally, the interconnectedness of global supply chains underscores the importance of international cooperation and collaboration in addressing these shared challenges. By working together, countries and businesses can share best practices, build common standards, and collectively strive to build a more resilient and stable global supply chain system.